Illustrate polymer properties with a self-siphoning solution

Demonstrate the tubeless siphon with poly(ethylene glycol) and highlight the polymer’s viscoelasticity to your 11–16 learners

Fuel curiosity in science careers

Help foster the next generation of scientists by linking teaching topics to real-world events and career pathways

Use AI to successfully assess students’ understanding

Discover how to quickly and effectively generate multiple choice questions on key chemistry topics

5 ways to successfully teach structure and bonding at 14–16

Strengthen students’ grasp of the abstract so they master this tricky topic and effectively tackle exam questions

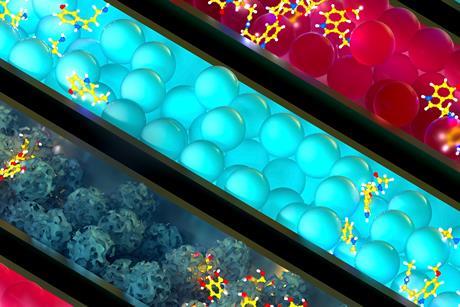

Illustrate polymer properties with a self-siphoning solution

Demonstrate concentration and density with a transition metal colloid cell

Highlight transition metal chemistry with an oscillating luminol reaction

Reversible reactions with transition metal complexes

Demonstrate changes of state using volume differences

- Previous

- Next

How visuospatial thinking boosts chemistry understanding

Encourage your students to use their hands to help them get to grips with complex chemistry concepts

Understanding how students untangle intermolecular forces

Discover how learners use electronegativity to predict the location of dipole−dipole interactions

3 ways to boost knowledge transfer and retention

Apply these evidence-informed cognitive processes to ensure your learners get ahead

Why we should ditch working scientifically

Explore a new approach to this this national curriculum strand, grounded in contemporary cognitive science

How do you feel about working in science education?

Tell us what it’s like by taking part in the Science teaching survey, and we can improve our support for you

Why I use video to teach chemistry concepts

Helen Rogerson shares why and when videos are useful in the chemistry classroom